Super Academic Discussion|The Development of Contact Lens

Posted by

Amy@Unicornsbeauty

Comments Off on Super Academic Discussion|The Development of Contact Lens

Contact lenses, as an important tool for vision correction and beauty, have experienced a long history and remarkable technological progress. If you are curious about the source of contact lenses, then you must not miss the following article.

Table of Contents

History of Contact Lens

- The first person to propose the concept of contact lenses -- Leonardo da Vinci, Italian polymath

In 1508, when the Italian polymath Leonardo da Vinci put his head into a half-spherical glass jar filled with water and looked down, he found that the previously invisible object became clear. At the time, he was not aware of the connection between this phenomenon and the correction of vision, but he did sketch this idea and elaborate the related concepts. He is credited as the pioneer of the Contact Lens concept, having penned the foundation of its history.

First attempt--ohn Herschel, English astronomer

In 1827, the British astronomer John Herschel proposed a design close to modern contact lenses. He covered a spherical glass sheet on the cornea and injected transparent glue between the glass and the eye in order to offset the uneven surface of the cornea and achieve the purpose of correcting astigmatism. But the cornea can feel, and there is no way to contact foreign matter, so his idea does not apply to the human body. It was not until 1884 that the use of anesthesia made a great breakthrough in the development of contact lenses.

- The world's first contact lens -- F.A. Muller, German glass technician

In 1887, German glass technician Muller made the world's first contact lenses with glass blowing, using glass to make the first pair of contact lenses that can be worn on the eyeball in human history, and also the first pair of hard contact lenses.

These lenses represent a significant milestone as the world's first wearable contact lenses. Muller's accomplishment paved the way for further advancements in contact lens technology.

Despite this groundbreaking innovation, early lenses posed significant challenges. The main drawback was their limited oxygen permeability. As a result, wearers could tolerate them for a mere 30 minutes before experiencing severe discomfort and pain. This limitation severely impeded their practical application and long-term usage.

- Improve your vision with glass lenses-- Adolf Eugen Fick, German ophthalmologist

Adolf Eugen Fick was one of the pioneers who initially explored the possibilities of utilizing glass lenses for correcting vision impairments. During the late 1880s, he carried out innovative experiments with the objective of improving visual acuity. Fick's research resulted in the creation of glass lenses that aimed to enhance eyesight. While these initial glass lenses were basic, they marked an extraordinary advancement in vision correction.

At the same time, the German medical student Augustus Muller is also in the lens related experiments, through the glass lens to improve their vision. In 1889, he published a paper that although he can let the lens into his eyes, but after half an hour, the eyes will produce severe pain. In this short half an hour, his myopia did improve.

- Hard contact lenses were born-- Istvan Gyorrfy in Hungary

In vision correction, innovation has often been driven by the quest for greater comfort and effectiveness. In 1937, Istvan Gyorrfy of Hungary began making rigid contact lenses from polymethyl methacrylate, commonly known as PMMA and its optical clarity and durability. This groundbreaking shift heralded the dawn of a new era in vision correction technology.

- The beginning of soft contact lenses-- Mullen and Theodore Obrig

In 1938, Mollen and Obker developed the technology of plastic lenses and produced the first all-plastic contact lenses by using PMMA. The key distinction of their lenses was the softness and flexibility, in stark contrast to the rigidity of earlier models. These lenses were made from a hydrophilic plastic material that has the capability to absorb and retain water. This feature enables the lenses to maintain a moist environment, reducing discomfort and enhancing their suitability for extended wear.

Obker also suggested using fluorescence to investigate the correlation between contact lenses and the corneal surface, paving the way for the fitting of contemporary contact lenses.

- Application of polyhydroxyethyl methacrylate-- Otto Wichterle, Czech scientist

In 1960, Otto Wechitler developed polyhydroxyethyl methacrylate (PHEMA). The resin was hydrophilic, indicating its ability to effectively absorb and retain water. This unique property allowed PHEMA to remain soft and pliable after absorbing water, making it exceptionally comfortable when placed on the eye.

Wearers could now enjoy clear vision without the discomfort of dry, rigid lenses. The global uptake of contact lenses experienced a substantial boost due to this development.

- Soft contact lens technology is introduced-- National Patent Company

In 1965, the National Patent Corporation introduced soft contact lens technology to the United States.

Soft contact lenses are a successful milestone in the development of contact lenses so far, and soft lenses account for 80% of the global contact lens market. The earliest soft mirror material, HEMA, was invented by Professor Otto Wichterle of the former Czechoslovak Academy of Sciences, and the results were patented in the United States in 1962 and 1965, and the technology was later acquired by Bausch & Lomb in the United States and entered the market in 1972.

- Father of soft contact lenses-- Otto Wichterle

In 1961, Otto Wichterle, Czechoslovakia polymer chemist, developed PHEMA material, which belongs to a hydrogel material and can be regarded as soft plexiglass. This material has been successfully applied to soft contact lenses. Compared with the hard lens, the soft contact lens is soft, less foreign matter sensation, and has certain air permeability.

- Soft contact lenses were born-- Bausch & Lomb

In 1966, Bausch & Lomb used the rotary mold method to produce soft contact lenses, and later produced and sold soft contact lenses in the United States, which made an epoch-making change in contact lenses. Because soft lenses are much more comfortable than hard lenses, and easy to adapt, they are welcomed by wearers, and quickly replaced the hard lens market.

- Manufacturing technology improvement-- American Optical Corporation

In 1967, the American Optical Company used a lathe to grind and manufacture soft contact lenses.

In 1976, the first semi-rigid contact lenses made of cellulose acetate butyrate (CAB) were introduced. Now, the lens made of fluorosilicone acrylate, fluoropolymer, silicon and other materials has better oxygen permeability, which is called hard permeable contact lens, referred to as RGP contact lenses.

- Mass production of disposable contact lenses-- Johnson & Johnson

In 1986, Johnson & Johnson revolutionized the production of soft contact lenses by implementing cast molds, resulting in significantly reduced costs. They also pioneered the promotion of disposable contact lenses, which gained tremendous popularity among consumers.

- RGP contact lenses-- Menicon

After the launch of the first RGP contact lens in 1979, Menicon developed ZOMA, a new material that can maintain a high level of oxygen permeability while ensuring a high level of strength.

In 1997, the ultra-thin bifaspherical design lens Menicon Z went on sale. Its DK value is as high as 163, and it still maintains the highest oxygen permeability coefficient in the world.

Menicon TINU, the pinnacle of Menicon RGP contact lenses in 2019, has become a cutting-edge work in the field of RGP contact lenses with extremely high safety, excellent comfort and clear visual quality.

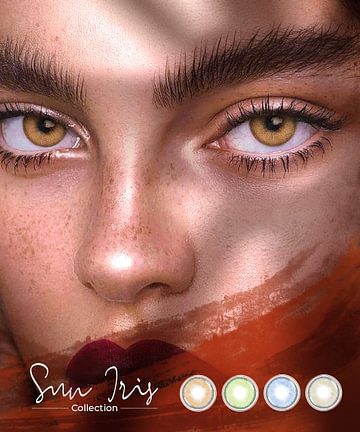

Three Main Technologies Used in Colored Contact Lenses

Colored contact lenses for individuals the opportunity to strengthen or change the eyes color has made significant progress. . Now, let's take a closer look at the three primary technologies utilized in colored contact lenses:

- Dry Printing Technology:

In-Depth Explanation: Dry printing technology involves applying the desired color to the surface of the contact lens, either on the outside or the inside. This process was once favored for its simplicity and cost-effectiveness. During manufacturing, the colored pigment was added to the lens material.

Advantages: This method was initially appealing due to its straightforward manufacturing process, which kept costs relatively low.

Drawbacks: However, dry printing had a significant downside - it resulted in easy fading of the color. The outer layer where the color was applied was prone to damage from wear and tear, exposure to tears, and other environmental factors.

Discontinuation: Due to the fading issues that plagued this technology, it was discontinued in 2010. Manufacturers were actively seeking more robust alternatives to preserve the vividness of colored contact lenses.

- Sandwich-Making Method:

In-Depth Explanation: The sandwich-making method, also known as the sandwich technique, revolutionized colored contact lens manufacturing. It involves placing the colored layer between two clear layers of the contact lens material, effectively "sandwiching" the pigment within the lens.

Advantages: This technology effectively solves the fading problem. By placing the pigmentation in the middle layers, it is better protected from external factors, leading to longer-lasting, vibrant colors.

Complex Production: The production process, however, is more intricate compared to dry printing, as it requires precision in layering and bonding the materials.

Wide Adoption: Many colored contact lenses available today employ the sandwich-making method due to its success in preventing color fading.

- Integral Coloring:

In-Depth Explanation: Integral coloring is a revolutionary technology that adds vibrant colors to a specific layer of the lens during the manufacturing process.

Advantages: Like the sandwich technique, integral coloring successfully combats the issue of fading,ensuring that the color remains vibrant.

Simplicity and Comfort: One of the notable advantages of integral coloring is the creation of a simpler type of colored contact lens. Wearers will feel comfortable and carefree while wearing these lenses。

These three technologies signify significant advancements in the manufacturing of colored contact lenses. While In Unicornsbeauty, it has taken advantage of the three main technologies, providing users with more durable and vibrant option. Consumers can now according to your preference for color, comfort and service life, make informed decisions when choosing color contact lenses.

The Difference between Contact Lenses and Color Contact Lenses

- Difference in Eye Care Functions : Contact lenses are lenses worn on the cornea of the eye for the purpose of correcting vision or protecting the eyes, designed for convenience in daily life. Circle lenses, on the other hand, are colored contact lenses that individuals with myopia can wear based on their prescription. Please be aware that individuals with severe myopia might not find both contact lenses and circle lenses suitable for their needs.

Circle lenses are specifically created to enhance the look of the eyes, featuring effects such as enlargement, brightening, or even changing the eye color.Regular contact lenses, however, are mainly used to correct vision and do not alter the appearance of the eyes.

- Differences in Appearance: Circle lenses have a larger diameter compared to regular contact lenses.As a result, they offer wider coverage for the eyes, giving the illusion of bigger and brighter eyes. A contact lens is a clear lens that is used to correct vision defects in the cornea, with the primary aim of maintaining optimal eye health and enhancing vision.

- Differences in Material: Contact lenses come in both soft and rigid gas-permeable varieties, while circle lenses are exclusively made of soft, hydrophilic materials. Circle lenses have colored layers to achieve their cosmetic effects.

- Differences in Maintenance Methods: Contact lenses have specialized care solutions for cleaning and disinfecting and should be stored in these solutions after each use. Circle lenses, due to their colored layers, cannot be soaked or cleaned with hydrogen peroxide-based contact lens care solutions.

- Differences in Oxygen Permeability:Circle lenses may have slightly lower oxygen permeability and protein resistance compared to regular contact lenses. This is because their primary purpose is cosmetic rather than extended, all-day wear. In contrast, regular contact lenses usually offer higher oxygen permeability and are designed for safe, extended daily wear.

- Differences in Wear Time: Circle lenses are typically designed for short-term wear and are not recommended for extended use. In comparison, regular contact lenses offer the convenience of being worn throughout the day, even while sleeping.

The Question about Colored Contact Lenses

Contact lenses are lenses worn on the cornea of the eye for visual correction or cosmetic decoration. Colored contact lenses are commonly known as "decorative color plain contact lenses", which is to add a colored coating on the basis of ordinary contact lenses to achieve decorative effects.

At present, most ordinary contact lenses use rotary cutting or injection mold cutting processes. Compared with the production process of ordinary contact lenses, colored contact lenses have more steps to dye.

The early popular dyeing process was to attach the pigment layer to the outside of the lens, which was easy to cause corneal staining. The current mainstream technology generally uses a "sandwich" process, in which two transparent layers wrap a pigment layer.

Due to the presence of heavy metal ions in the coating for dyeing, its oxygen permeability is worse than that of ordinary colored contact lenses, so it is more necessary to pay attention to the length of wear.

Whether colored contact lenses are safe has always been a topic of great concern to everyone, we can discuss from two questions.

The first question is: Are colored contact lenses really safe?

The mainstream regular colored contact lenses are "sandwich" structures. As the name suggests, the pigment is sandwiched between two transparent lenses so that the pigment does not directly contact the eye. However, because the "sandwich" structure is difficult to make and has patent protection, some poor quality cosmetic contact lens manufacturers will only be in the surface coating, extremely prone to fading or fading phenomenon, resulting in corneal staining, easy to cause corneal infection, please pay attention to identification.

It is also important to remember that colored contact lenses are not cosmetics or ornaments, but a strictly regulated medical device, so be sure to buy regular brand colored contact lenses.

The second question is: Do colored contact lenses thin the cornea?

The answer is probably yes! It depends on whether it is used cleanly and worn properly. Wear specifications include, but are not limited to:

(1) Check whether the degree is appropriate, generally speaking, the contact degree range is slightly different from the frame glasses, the conversion formula is: contact lens diopter = frame glasses diopter ÷ (1-0.012× frame glasses diopter) (1 diopter is equivalent to 100 degrees);

(2) Keep hands dry and clean when wearing;

(3) Regularly remove and replace the lens, do not wear to sleep;

(4) Non-daily lenses need to be cared for.

Gold

Gold